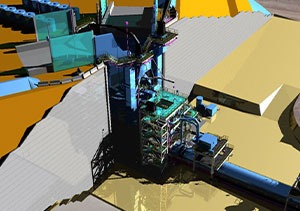

PRIMARY CRUSHING AND CONVEYING IN A COMPLETE SOLUTION

TNT’s proven design methodologies are a critical foundation to the development of high-capacity primary crushing stations used in large hard rock mining applications.

TNT integrates our custom modular steel stations with the downstream plant and processing facilities as a complete solution. Our in-depth knowledge of plant layout and experience supplying high-capacity in-plant and overland conveying ensures highly efficient, cost effective and reliable solutions connecting the mining and mineral processing operations.

Our plant specialists work collaboratively with equipment manufacturers to ensure the entire system is reliable, meets the process requirements and is fit for purpose. TNT can work with client preferred vendors or recommend the best equipment from both a technical and commercial perspective.

KEY BENEFITS OF TNT’S PRIMARY CRUSHING STATIONS

Modularized design

We bring larger fabricated pieces and pre-assembled modules to site, providing a quicker, safer and more cost-effective construction process.

High Availability

Our systems are developed to maximize equipment reliability and station availability, built tough enough to meet the challenges of any mine site.

Performance

We design our crushing stations for maximize operability and maintainability, ensuring optimal performance for its lifetime.

Fully customized

We custom design systems in accordance with client’s or project specific requirements considering all aspects of logistics, resource availability, schedule and cost.

TAILORED SOLUTIONS TO MEET YOUR NEEDS

No matter the nature or scope of the job, we work to your requirements. While our approaches may vary, the quality of outcomes don’t.

We can supply and design custom primary stations and liaise directly with a third-party crusher OEMs to optimize equipment selection. Alternatively, we can design an effective crushing station solution using customer-supplied crushers.

TNT CRUSHING PLANTS. BUILT TO LAST

TALK TO US

Talk to us about your project.